The ULTIMATE SAFETY TEST

“Sustainability is now as important as safety to us.”

We have dedicated our business to help protect the lives of people both inside and outside of our cars. We will now show the same dedication to help protect the planet.

We are part of the problem so we need to be part of the solution.

Our ambition is to become a climate neutral company by 2040. However, electrifying our fleet is not enough. We need to address emissions across our value chain. This involves using greater climate neutral energy in both our own operations and among our suppliers, as well as making better use of materials and components. But we need to act now. So, we are aiming to reduce our lifecycle emissions per vehicle by 40 per cent by 2025.

A global transition to electrified cars is essential if the world is to reach net zero emissions by 2050, and to limit the impacts of climate change. By 2025, we are aiming for 50 per cent of our sales to be fully electric, and by 2030 we will only produce fully electric vehicles.

Our new flagship showroom will be right here on this site. You will be able to start your order online for our fully electric cars, making it as easy as possible to choose a car with no tailpipe emissions.

Our new flagship showroom will be right here on this site. Our ambition is to also enable more online offers and services, making it as easy as possible to choose a car with no tailpipe emissions.

Initiatives that make a difference

Leather-free

Leather-free

Our fully electric cars will be 100 per cent leather-free, starting with the introduction of our new C40 Recharge. In doing so, we are taking a stand for animal welfare. Instead of leather, we offer our customers high-quality, sustainable materials made from bio-based and recycled sources.

Climate neutral manufacturing

Climate neutral manufacturing

Volvo Cars aims to have global climate neutral manufacturing operations by 2025. We are working towards this through sourcing and producing our own climate neutral energy, as well as increasing energy efficiency at our plants. We are making good progress. All our European plants have run on renewable electricity since 2008, and in 2020 our global plants were powered by 51 per cent climate neutral energy. Our largest Chinese plant in Chengdu recently secured a 100 per cent climate neutral electricity supply.

Maximising remanufacture

Maximising remanufacture

Compared to producing new parts, remanufactured parts use around 85 per cent less raw material and 80 per cent less energy. We currently remanufacture over 50 different parts, including engines, gearboxes, turbo compressors and clutches. In 2020 we saved almost 3,000 tonnes of CO2 by remanufacturing over 40,000 parts.

Minimising production waste

Minimising production waste

In 2020, 95 per cent of our global production waste was recycled, meaning that we not only avoided creating additional carbon emissions, but we were able to keep valuable material in circulation and reduce the amount of virgin material that needed to be produced. The vast majority of waste we recycle is steel. In 2020, we recycled over 176,000 tonnes, avoiding the generation of nearly 640,000 tonnes of CO2.

An aligned retailer network

An aligned retailer network

We’re working with our retailers to ensure our entire network is climate neutral by 2040. This involves driving efficiency measures and ensuring a greater use of renewable energy in every part of their business. A number of our retailers across the world already have their own on-site renewable energy supply.

Responsible cobalt sourcing

Responsible cobalt sourcing

Cobalt is a vital component in the production of electric car batteries. In some cases, the extraction of cobalt can have human rights impacts. We use blockchain technology to increase transparency and traceability of our cobalt supply chain ensuring that information about the material’s origin cannot be changed undetected. We use several other processes, in conjunction with our suppliers, including mine site inspections and GPS tracking to help ensure that the cobalt within our batteries is responsibly sourced.

Leather-free

Our fully electric cars will be 100 per cent leather-free, starting with the introduction of our new C40 Recharge. In doing so, we are taking a stand for animal welfare. Instead of leather, we offer our customers high-quality, sustainable materials made from bio-based and recycled sources.

Climate neutral manufacturing

Volvo Cars aims to have global climate neutral manufacturing operations by 2025. We are working towards this through sourcing and producing our own climate neutral energy, as well as increasing energy efficiency at our plants. We are making good progress. All our European plants have run on renewable electricity since 2008, and in 2020 our global plants were powered by 51 per cent climate neutral energy. Our largest Chinese plant in Chengdu recently secured a 100 per cent climate neutral electricity supply.

Maximising remanufacture

Compared to producing new parts, remanufactured parts use around 85 per cent less raw material and 80 per cent less energy. We currently remanufacture over 50 different parts, including engines, gearboxes, turbo compressors and clutches. In 2020 we saved almost 3,000 tonnes of CO2 by remanufacturing over 40,000 parts.

Minimising production waste

In 2020, 95 per cent of our global production waste was recycled, meaning that we not only avoided creating additional carbon emissions, but we were able to keep valuable material in circulation and reduce the amount of virgin material that needed to be produced. The vast majority of waste we recycle is steel. In 2020, we recycled over 176,000 tonnes, avoiding the generation of nearly 640,000 tonnes of CO2.

An aligned retailer network

We’re working with our retailers to ensure our entire network is climate neutral by 2040. This involves driving efficiency measures and ensuring a greater use of renewable energy in every part of their business. A number of our retailers across the world already have their own on-site renewable energy supply.

Responsible cobalt sourcing

Cobalt is a vital component in the production of electric car batteries. In some cases, the extraction of cobalt can have human rights impacts. We use blockchain technology to increase transparency and traceability of our cobalt supply chain ensuring that information about the material’s origin cannot be changed undetected. We use several other processes, in conjunction with our suppliers, including mine site inspections and GPS tracking to help ensure that the cobalt within our batteries is responsibly sourced.

Our commitment to setting the highest standards of sustainability in mobility.

The shape of things to come

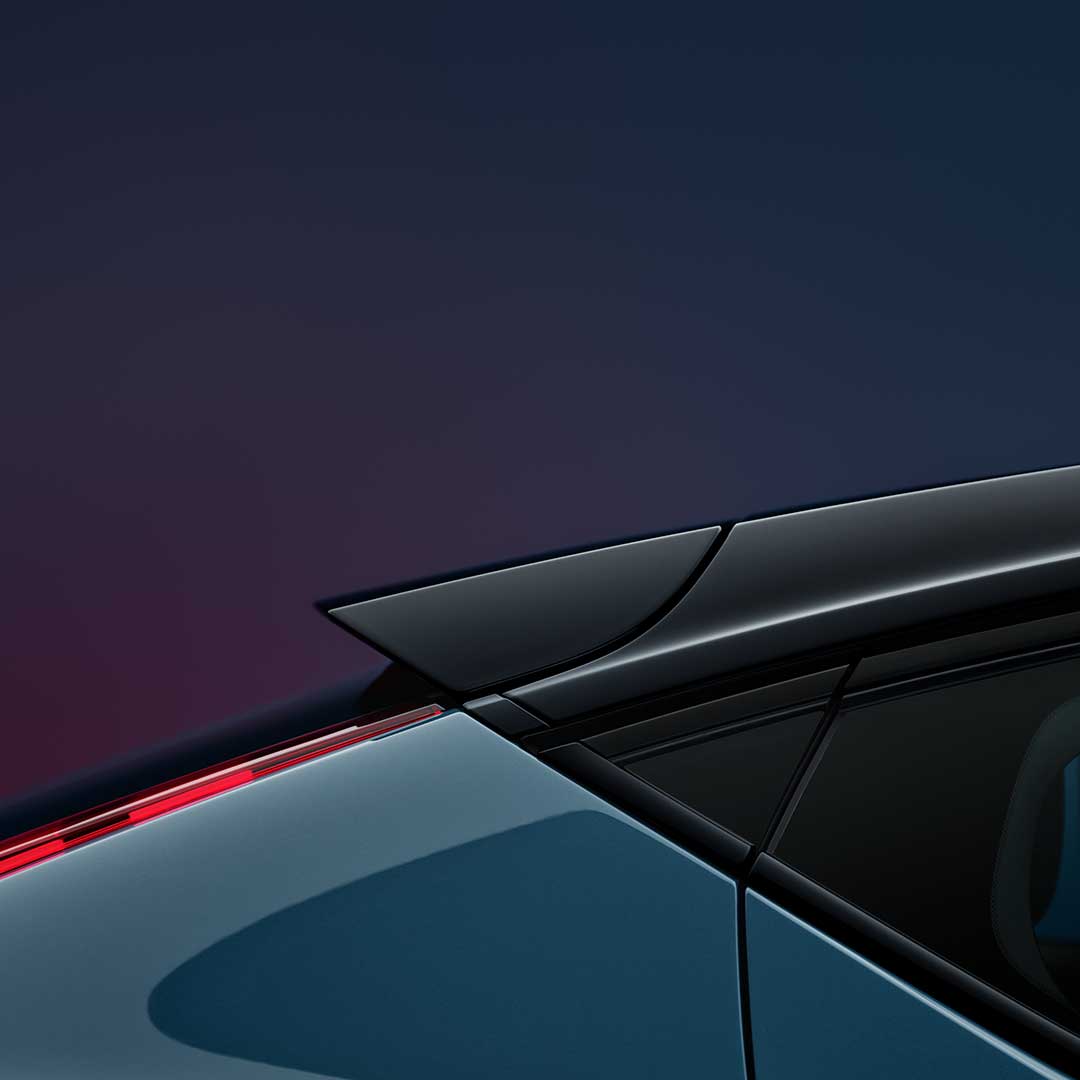

The C40 Recharge is our first ever Volvo to be launched only as an electric model, designed to reduce environmental impact. Inside, a leather-free interior represents a new interpretation of luxury while our reassuring safety features remain as vital as ever.

Designed with purpose

Discover XC40 Recharge – our full electric compact SUV, designed for modern urban living and beyond. Start your online order today.

Sustainable materials

Increasing the use of sustainable materials is just one way the XC40 Recharge helps reduce its environmental impact.

Zero compromise

The twin electric motors mean there are zero tailpipe emissions, keeping your drive as clean as possible.

Discover the benefits

With maintenance service, insurance coverage and extended warranty included, you can start your journey with peace of mind.

Car features depicted may not be standard or available for all styles and engine options.