Changing wheel

Wheel changes must always be performed correctly. Instructions on how a wheel is removed and mounted and what is important to remember are provided below. Check that the tyre dimension is approved for use on the car.

Warning

- If a wheel must be changed in a trafficked environment, passengers must stand in a safe place.

- Use a jack designed for the car when changing tyres. Use supports to secure the car for all other work.

- Never crawl under the car or reach under with a part of your body when it is raised on a jack.

- Passengers must leave the car when it is raised on the jack.

Important

- When the jack* is not in use it must be stored in its storage space under the cargo area floor.

- The jack included with the car is only designed for occasional, short-term use, such as when changing a wheel after a puncture. Only the jack belonging to the specific model is to be used to jack up the car. If the car is to be jacked up more often, or for a longer time than is required just to change a wheel, use of a garage jack is recommended. In this instance, follow the instructions for use that come with the equipment.

Removing a wheel

Read through all instructions before beginning. Take out the tools needed before jacking up the car.

Set up the warning triangle and activate the hazard warning lights if a tyre is being changed in a trafficked location.

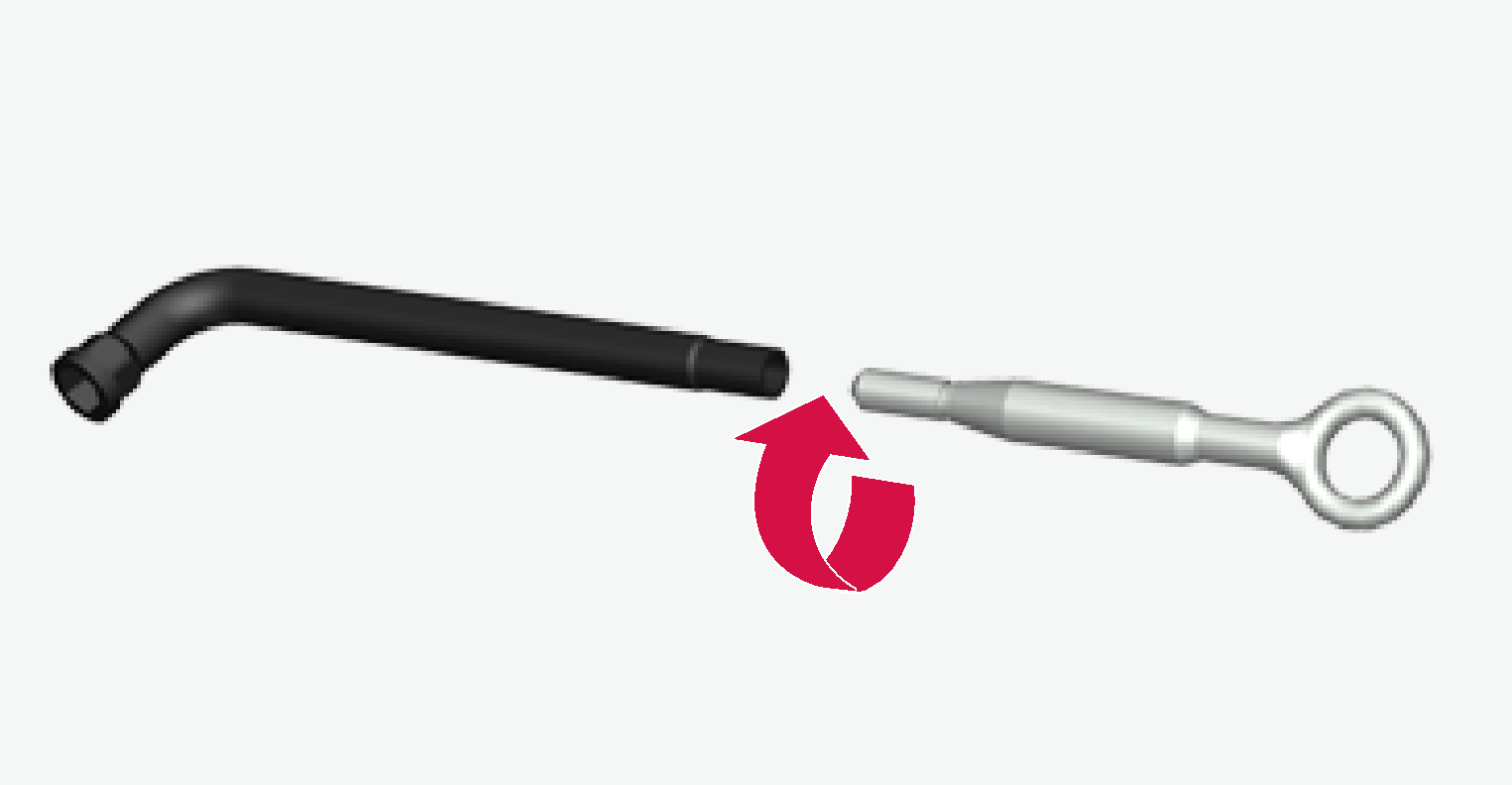

Screw together the towing eye with the wheel wrench to the stop position.

Remove the plastic caps from the wheel bolts with the intended tool.

With the car still on the ground, use the wheel bolt wrench/towing eye to undo the wheel bolts ½-1 turn by pressing downwards (anticlockwise). Always start with the lockable wheel bolts*.

Follow the instructions for how to safely raise the car with the jack.

Raise the car high enough to allow the wheel to be removed to move freely. Remove the wheel bolts and lift off the wheel.

Mounting a wheel

Clean the surfaces between wheel and hub.

Put on the wheel. Tighten the wheel bolts thoroughly.

Do not use lubricant on the threads of the wheel bolts.

Lower the car so that the wheels cannot rotate.

Tighten the wheel bolts crosswise. It is important that the wheel bolts are tightened properly. Tighten to 140 Nm (103 foot-pound). Check the tightening torque with a torque wrench.

Refit the plastic caps on the wheel bolts.

Check the tyre pressure and save the new tyre pressure in the system for tyre pressure monitoring*.

Warning

The wheel bolts may need to be re-tightened several days after the wheel change. Temperature differences and vibration may mean that they are not attached equally as tightly.

Note

- After a tyre has been inflated, always refit the dust cap in order to avoid damage to the valve from gravel, dirt, etc.

- Only use plastic dust caps. Metal dust caps can rust and become difficult to unscrew.