Removing a wheel

Wheel changes must always be performed correctly. Instructions on how a wheel is undone and what is important to remember are provided below.

Important

- When the jack* is not in use it must be stored in its storage space under the cargo area floor.

- The jack included with the car is only designed for occasional, short-term use, such as when changing a wheel after a puncture. Only the jack belonging to the specific model is to be used to jack up the car. If the car is to be jacked up more often, or for a longer time than is required just to change a wheel, use of a garage jack is recommended. In this instance, follow the instructions for use that come with the equipment.

Warning

- Apply the parking brake and set the gear selector in Park position (P).

- Chock the wheels standing on the ground using solid wood blocks or large stones.

- Check that the jack is not damaged, that the threads are thoroughly lubricated and that it is free from dirt.

- Check that the jack is resting on a firm, level surface that is not slippery and is not slanted.

- The jack must be correctly attached in the jack's bracket.

- Never position anything between the ground and the jack, nor between the jack and the car's jacking point.

- Passengers must leave the car when it is raised on the jack.

- If a wheel must be changed in a trafficked environment, passengers must stand in a safe place.

- Use a jack designed for the car when changing tyres. Use supports to secure the car for all other work.

- Never crawl under the car or reach under with a part of your body when it is raised on a jack.

Set up the warning triangle and activate the hazard warning lights if a tyre is being changed in a trafficked location.

Chock in front of and behind the wheels that remain on the ground. Use, for example, heavy wooden blocks or large stones.

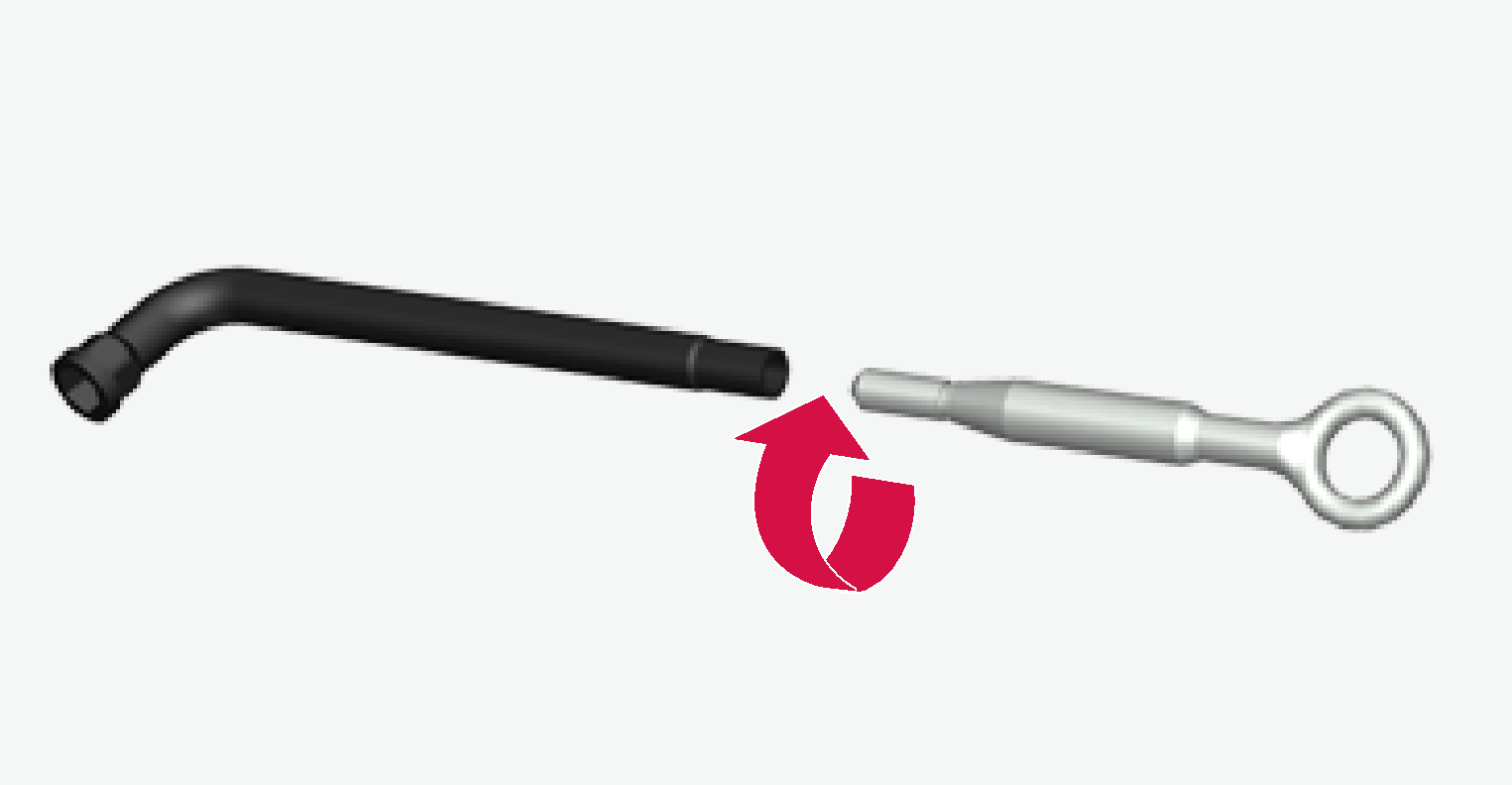

Screw together the towing eye with the wheel wrench until the stop position as per the instructions.

Important

The towing eye must be screwed into the wheel bolt wrench* as far as possible.

Remove the plastic caps from the wheel bolts with the intended tool.

With the car still on the ground, use the wheel bolt wrench/towing eye to undo the wheel bolts ½-1 turn by pressing downwards (anticlockwise).

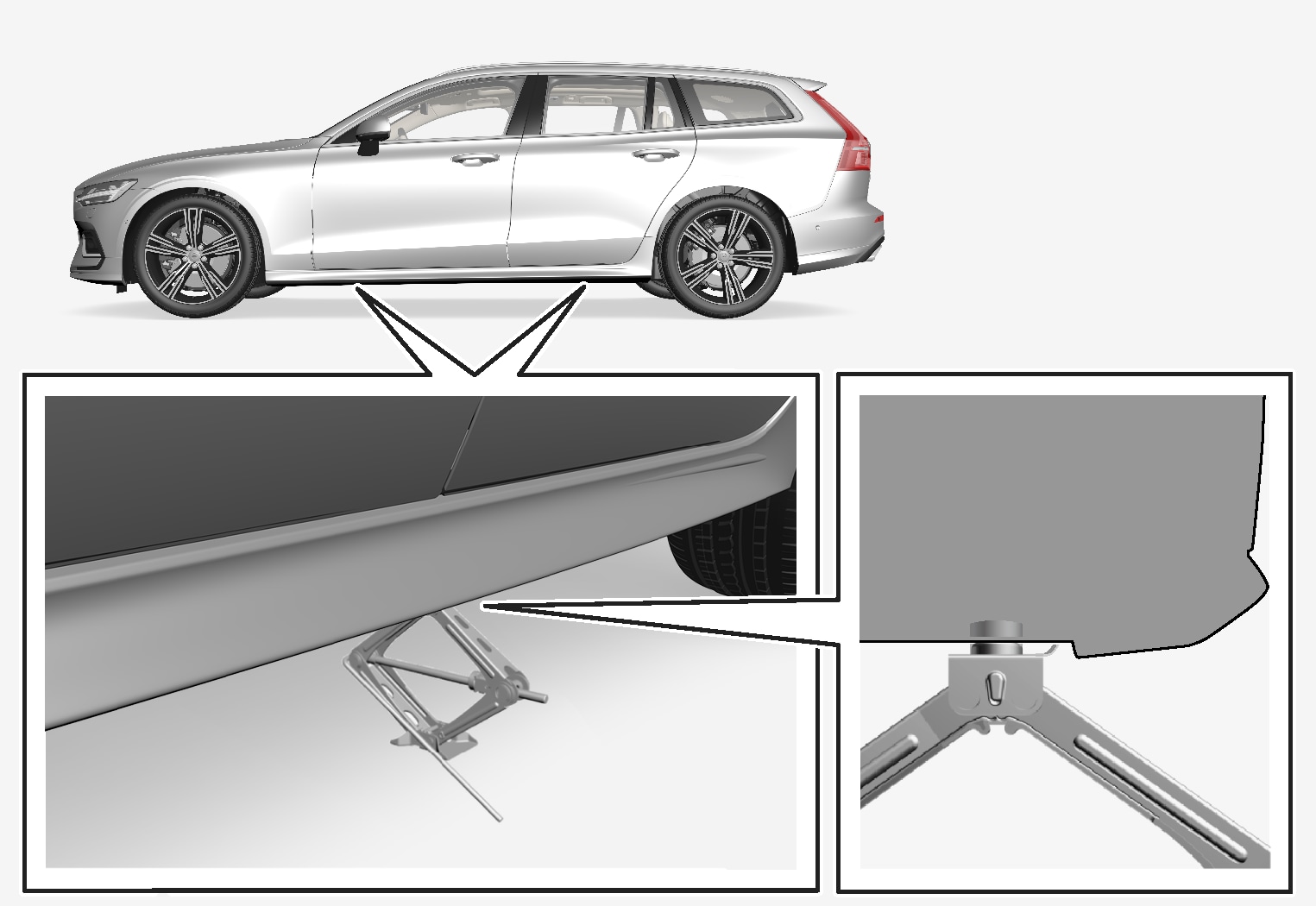

When raising the car, it is important that the jack or lifting arms are fitted in the intended points on the car's underbody. The triangle markings in the plastic cover indicate the locations of the jacking/lifting points. There are two jacking points on each side of the car. There is a recess for the jack at each point.

Position the jack on level, firm and non-slippery ground under the jacking point that will be used.

Crank up until it is correctly aligned and so that it makes contact with the car's jacking point. Check that the head of the jack (or the lift arms at a workshop) is correctly positioned in the jacking point so that the bump in the centre of the head fits into the jacking point hole and the base is positioned vertically below the jacking point.

Turn the jack so that the crank is as far away from the side of the car as possible, at which point the jack's arms are perpendicular to the direction of the car.

Raise the car high enough to allow the wheel to be removed to move freely. Remove the wheel bolts and lift off the wheel.