Emergency puncture repair* - operation

Sealing a puncture with the emergency puncture repair kit, Temporary Mobility Kit (TMK).

Emergency puncture repair

Set up the warning triangle and activate the hazard warning lights if a tyre is being sealed in a trafficked location.

If the puncture was caused by a nail or similar, allow this to remain in the tyre. It helps to seal the hole.

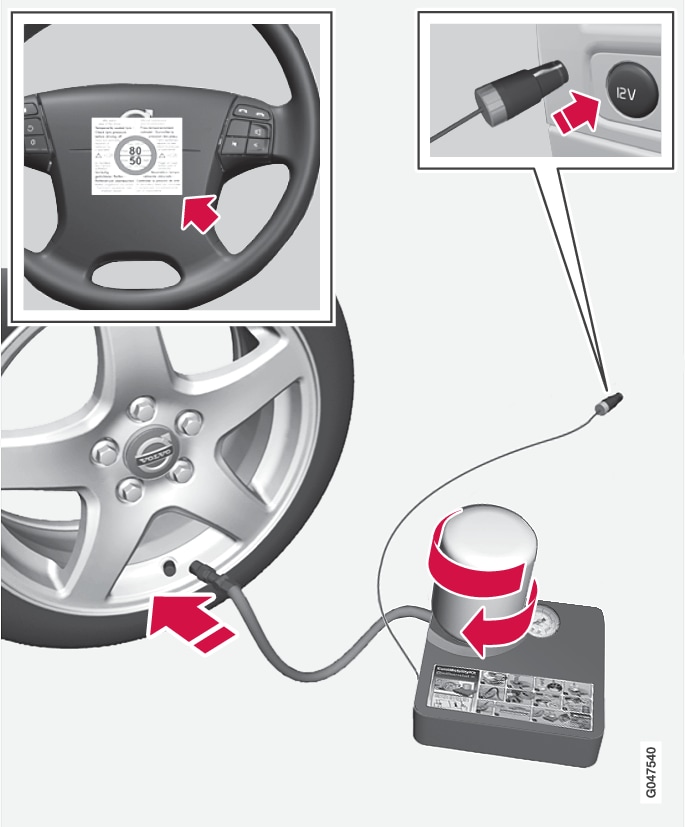

Detach the label for maximum permitted speed (which is fitted on one side of the compressor) and affix it to the steering wheel. You should not drive faster than 80 km/h (50 mph) after the emergency tyre repair kit has been used.

Check that the switch is in position 0, and take out the electrical cable and the air hose.

Unscrew the orange-coloured cap from the compressor, and unscrew the cork from the bottle.

Note

Do not break the bottle's seal before use. The seal is broken automatically when the bottle is screwed in.

Screw in the bottle to the bottom of the bottle holder.

The bottle and the bottle holder are equipped with a reverse catch to prevent sealant leakage. When the bottle is screwed in it cannot be unscrewed from the bottle holder again. Bottle removal must be performed at a workshop, Volvo recommends an authorised Volvo workshop.

Warning

- In the event of skin contact with the sealing fluid, it must be washed off immediately with soap and plenty of water.

- Sealing fluid that makes contact with an eye must be rinsed away immediately with eye wash fluid or with plenty of water. If the discomfort persists then the eye should be examined by a doctor.

Warning

Do not unscrew the bottle, it is equipped with a reverse catch to prevent leakage.

Unscrew the tyre's dust cap.

Check that the pressure reducing valve on the air hose is fully screwed on, and screw in the air hose's valve connection to the bottom of the thread on the tyre's air valve.

Plug the electrical cable into the closest 12 V socket and start the car.

Note

Make sure that none of the other 12 V sockets is in use when the compressor is operating.

Warning

Do not leave children in the car without supervision when the engine is running.

Start the compressor by flicking the switch to position I.

Warning

Never stand next to the tyre when the compressor is running. If cracks or unevenness arise then the compressor must be switched off immediately. The journey should not be continued. Contacting an authorised tyre centre is recommended.

Note

When the compressor starts, the pressure can increase up to 6 bar but the pressure drops after approximately 30 seconds.

Inflate the tyre for 7 minutes.

Important

The compressor must not be operated for longer than 10 minutes - risk of overheating.

Switch off the compressor to check the pressure on the pressure gauge. Minimum pressure is 1.8 bar and maximum 3.5 bar. (Release air with the pressure reducing valve if the tyre pressure is too high.)

Warning

If the pressure is below 1.8 bar then the hole in the tyre is too big. The journey should not be continued. Contacting an authorised tyre centre is recommended.

Switch off the compressor and unplug the electrical cable.

Unscrew the air hose from the tyre's air valve and refit the dust cap on the tyre.

Fit the protective cap on the air hose in order to avoid leakage of the remaining sealing fluid.

As soon as possible, drive at least 3 km at a maximum speed of 80 km/h (50 mph) so that the sealing fluid can seal the tyre.

Note

Sealant will spurt out of the puncture during the first few rotations of the tyre.

Warning

Make sure that nobody is standing near the car and gets the sealing fluid splashed onto them when the car is driven away. The distance should be at least two metres.

Follow-up inspection:

Connect the air hose on the tyre's air valve again and check the tyre pressure with the pressure gauge, see Emergency puncture repair* - rechecking.