Changing a wheel

Warning

- If a tire must be changed near passing traffic, make sure all passengers move to a safe location.

- Use a jack* intended for the vehicle when changing a tire. For any other job, use stands to support the vehicle.

- Never crawl under or allow any part of your body to be extended under a vehicle supported by a jack.

- Never let anyone remain in the vehicle when it is raised on a jack.

Important

If a jack* is provided with your vehicle, it is intended to be used only in temporary situations such as changing wheels in the event of a flat tire. Only the jack that came with your particular model should be used to lift the vehicle. If the vehicle needs to be lifted more frequently, or for a longer period of time than for a wheel change, a garage jack or hoist is recommended. Always follow this device's instructions for use.

When not in use, the jack should be kept in its storage compartment under the trunk floor. Crank the jack to the correct position so that it fits.

Removing a wheel

Turn on the vehicle's hazard warning flashers if a wheel change must be performed in an area with traffic.

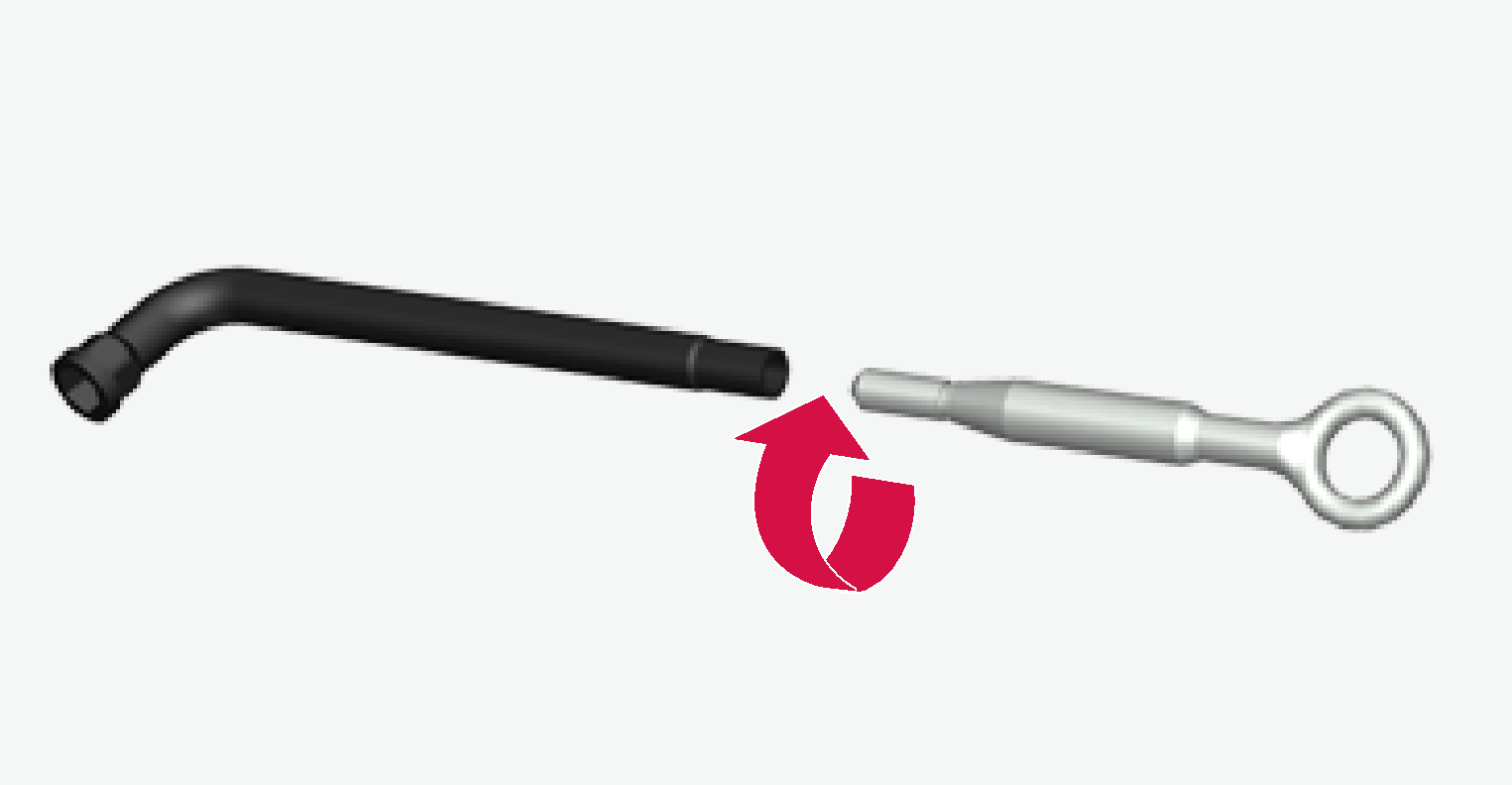

Using the lug wrench*, screw the towing eye into place as far as possible.

Remove the plastic covers from the wheel bolts using the designated tool or pull off the wheel cap.

Installing a wheel

Lift the wheel into place. If the vehicle has tires or wheels of different sizes on the front and back, make sure the correct dimensions are used for each position. Tighten the wheel bolts securely.

Do not grease the wheel bolt threads.

Tighten the wheel bolts in a crisscross pattern (as shown in illustration). It is important that the wheel bolts are securely tightened. Tighten to 140 Nm (103 ft. lbs.). Use a torque wrench to check torque.

- Replace the wheel cap over the wheel bolts by aligning it with the guide marks and then pressing it into place.

- Press the plastic covers over the wheel bolts.

Warning

Note

- After inflating a tire, always replace the valve cap to help prevent valve damage caused by gravel, dirt, etc.

- Use plastic valve caps only. Metal caps could corrode and become difficult to remove.