Removing a wheel

Wheel changes must always be carried out correctly. The following instructions show how to remove a wheel and what is important to keep in mind.

Important

- When not in use, the jack* should be kept in its storage compartment under the cargo compartment floor.

- The jack provided with your vehicle is intended to be used only in temporary situations such as changing wheels in the event of a flat tire. Only the jack that came with your particular model should be used to lift the vehicle. If the vehicle needs to be lifted more frequently or for a prolonged period, using a garage jack or hoist is recommended. Always follow this device's instructions for use.

Warning

- Apply the parking brake and put the gear selector in the Park (P) position.

- Block the wheels standing on the ground, use rigid wooden blocks or large stones.

- Check that the jack is not damaged, the threads are properly lubricated and it is free from dirt.

- Be sure the jack is on a firm, level, non-slippery surface and that it is upright and not leaning.

- The jack must correctly engage in the jack attachment.

- No objects should be placed between the base of the jack and the ground, or between the jack and the attachment bar on the vehicle.

- Never let anyone remain in the vehicle when it is raised on a jack.

- If a tire must be changed near passing traffic, make sure all passengers move to a safe location.

- Use a jack intended for the vehicle when changing a tire. For any other job, use stands to support the vehicle.

- Never crawl under or allow any part of your body to be extended under a vehicle supported by a jack.

Turn on the vehicle's hazard warning flashers if a wheel change must be performed in an area with traffic.

Place chocks in front of and behind the wheels that are still on the ground. For example, use heavy wooden blocks or large stones.

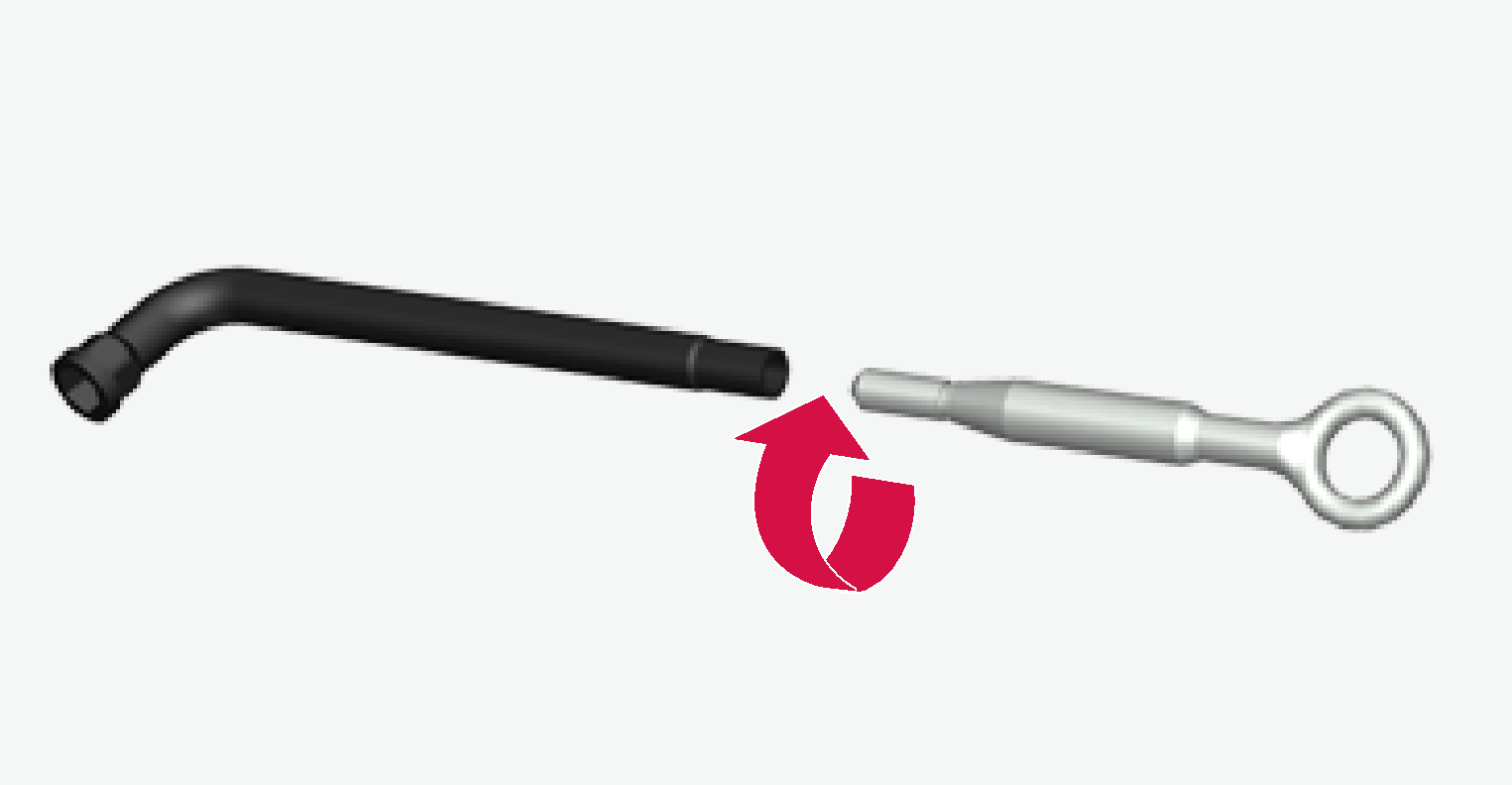

Using the lug wrench, screw the towing eye into place as far as possible according to the instructions.

Important

The towing eyelet must be screwed into the lug wrench* as far as possible.

Remove the plastic covers from the wheel bolts using the designated tool.

With the vehicle still on the ground, use the lug wrench/towing eye to loosen the wheel bolts ½-1 turn by pressing downward (counterclockwise).

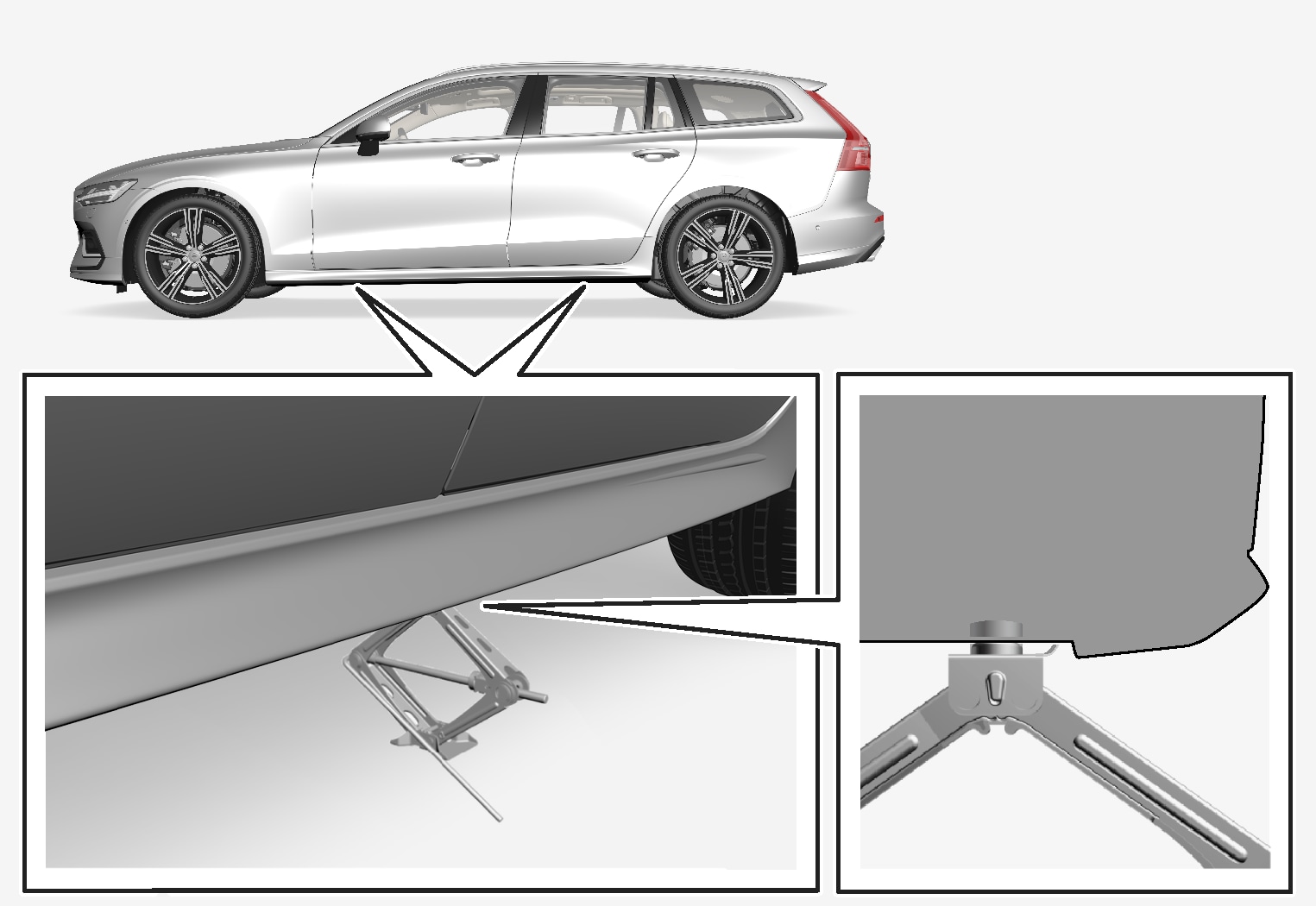

When hoisting the vehicle, it is important that the jack or garage lift arms are positioned on the designated points under the vehicle. The triangle markings on the plastic cover indicate where the jack attachment points/lifting points are located. There are two jack attachment points on each side of the vehicle. There is a groove for the jack at each attachment point.

Position the jack under the attachment point being used, ensuring that the surface is firm, flat and not slippery.

Crank it up until it is properly aligned and it is in contact with the vehicle's jack attachment point. Make sure the top of the jack (or the garage lift arms) is correctly positioned in the attachment point, with the bump on the top of the jack in the recess in the attachment point and the base positioned vertically under the attachment point.

Turn the jack so that the crank is as far as possible from the side of the vehicle, which will position the jack's arms perpendicular to the vehicle's direction of movement.

Raise the vehicle until the wheel to be changed can move freely. Unscrew the wheel bolts and lift off the wheel.